Introduction on AI-based Vision Inspection Solution

In today’s fiercely competitive manufacturing landscape, the drive for efficiency has never been more critical. Customers demand top-notch product quality, and manufacturers are under increasing pressure to deliver while optimizing processes and cutting costs. In the global manufacturing arena, the decision to embrace automation and AI-driven solutions is not just a matter of staying ahead- it’s a strategic imperative.

According to a recent report by McKinsey, the market dynamics around automation and AI in manufacturing are evolving rapidly. In regions like Vietnam, where labor costs have traditionally been a primary consideration, the business case for automation has faced challenges. The report highlights that the ease of automation adoption and the return on investment can vary significantly, contingent on sector-specific readiness and the availability of technology. For instance, while the automotive industry has readily embraced robotics, garment, and textiles producers have encountered unique challenges in automating processes like sewing. However, as labor costs continue to rise and manufacturers vie for higher value-added products, the rationale for automation becomes increasingly compelling. In sectors such as apparel, it’s estimated that automation can slash labor time by 40 to 70 percent [1], making traditionally higher-cost locations more competitive. Moreover, as market dynamics shift towards demand-led sourcing and production, speed and agility are gaining precedence over traditional low-cost outsourcing.

In this blog, we explore the transformative power of AI solutions in manufacturing quality assurance. We delve into how these advancements align with the evolving market dynamics, paving the way for manufacturers to not only meet but exceed customer expectations. As the manufacturing world stands at the cusp of change, the question of “Where?” to implement automation and AI is paramount. Our journey begins by understanding the opportunities for automation that make economic sense in today’s highly integrated supply chain landscape, where productivity gains must be weighed against the investment in automation.

Understanding Manufacturing QA/QC

Quality Assurance (QA) and Quality Control (QC) in the context of manufacturing is the systematic process of ensuring that products meet established quality standards, specifications, and customer expectations consistently. It encompasses a set of procedures, policies, and activities that monitor and control various stages of the manufacturing process to prevent defects, deviations, or inconsistencies in the final products. QA/QC plays a pivotal role in manufacturing for several reasons. Firstly, it safeguards product quality, ensuring that every item leaving the production line meets the intended specifications. Secondly, it enhances safety by identifying and rectifying potential hazards or defects that could pose risks to consumers. Lastly, it ensures compliance with industry-specific regulations and standards, which is crucial for maintaining market competitiveness and avoiding legal repercussions.

Traditional QA/QC methods have long relied on manual inspections, sample testing, and statistical process control to identify defects or deviations. While these methods have been effective to a certain extent, they come with limitations. Manual inspections are labor-intensive, subject to human error, and may not detect subtle defects. Sample testing offers only a limited view of product quality, leaving room for undetected issues in non-sampled items. Statistical process control can be complex and may not catch rare or sporadic anomalies. As manufacturing processes have evolved in complexity and scale, traditional QA/QC methods have shown their inadequacy in addressing modern manufacturing challenges. This is where innovative AI solutions come into play, offering the potential to enhance QA/QC processes, improve accuracy, and adapt to dynamic production environments.

The AI Revolution in Manufacturing

The manufacturing industry is experiencing a transformative wave, driven by the rapid integration of Artificial Intelligence (AI) technologies. AI has emerged as a powerful catalyst, reshaping how QA/QC processes are conducted. Unlike traditional methods, AI-powered systems can analyze vast volumes of data in real time, making them exceptionally adept at identifying defects, anomalies, and variations that might escape human observation. This ability to detect issues swiftly and accurately is revolutionizing QA/QC, allowing manufacturers to maintain a high level of product quality while streamlining their processes. One of the key advantages of incorporating AI in QA/QC is its capacity to enhance efficiency. AI-driven systems can operate 24/7, ensuring continuous monitoring and immediate response to deviations from quality standards. This not only reduces the need for manual inspections but also minimizes the risk of defective products reaching consumers. Additionally, AI’s adaptive nature enables it to learn and adapt to changing manufacturing conditions, making it invaluable in environments characterized by variability and complexity. As a result, manufacturers benefit from reduced defects, improved productivity, and the ability to meet stringent quality demands in a highly competitive market. The AI revolution in manufacturing QA/QC is poised to reshape the industry’s landscape, offering manufacturers a powerful tool to ensure product quality, safety, and compliance at unprecedented levels.

Introducing the AI-based Vision Inspection

Introducing our cutting-edge AI solution tailored for the manufacturing industry, designed to revolutionize quality control processes. Our innovative solution automates inspection tasks, enabling manufacturers to seamlessly detect defective products with unmatched precision and efficiency. What sets our solution apart is its unique combination of two robust approaches: edge client solutions and centralized cloud-based processing. This harmonious fusion harnesses the strengths of both edge and cloud computing, supercharging manufacturing quality control.

The AI-based Vision Inspection consists of two major components:

- Edge Client Solutions: At the forefront of our solution, edge client solutions are the driving force operating directly on the manufacturing floor, or at the “edge” of the network. These encompass a comprehensive ecosystem of hardware, software, algorithms, and processes primed to analyze data in real time. Our end-to-end edge client solution for customers comprises several integral components:

- Camera: Within the realm of manufacturing, various case studies demand inspection. Fixed camera configurations aren’t a one-size-fits-all solution. In response, our camera setup is highly adaptable to address diverse challenges. Furthermore, we meticulously construct an ideal environment for observing samples, ensuring optimal inspection outcomes. Our setup can integrate 5 world-class camera brands including Basler, iRAYPLE, IDS, Dino-Lite, and HIKROBOT, in which the max supported resolution is up to 100M pixels. Additionally, we appreciate the collaborations with the third parties who provide the lighting and lens solutions to enhance our camera setup.

- AI Boxes: Encompasses a holistic approach that seamlessly combines hardware and software elements. When working with clients, our consulting team meticulously assesses several critical parameters, including budget constraints, performance expectations, and the imperative for real-time, low-latency applications. On the software front, we employ cutting-edge technology to craft a custom solution tailored to the client’s unique requirements. This software serves as the cornerstone of our AI-based vision inspection solution, empowering it to deliver real-time, high-precision analysis and decision-making capabilities.

- Programmable Logic Controller (PLC): In the dynamic world of manufacturing, products often traverse one or more conveyors, assuming different poses when captured by the camera. Our solution incorporates physical preprocessing steps locally to mitigate source distortions effectively.

- Software Application: In the early stages of delivering AI solutions in manufacturing, the guidance of a quality assurance engineer is invaluable. This online testing phase is pivotal in assessing the AI solution’s real-world performance. To facilitate this, we’ve developed a user-friendly software application, enabling field engineers to swiftly identify and rectify any issues that may arise during machine uptime.

- Centralized Management: Complementary to our edge client solutions, centralized management entails the practice of delegating data processing and analysis tasks to remote servers or cloud infrastructure. This approach accommodates the management of multiple production lines within a single factory or across geographically dispersed facilities. The process initiates with the collection of data from manufacturing processes, including images, sensor readings, and other pertinent information, which is then transmitted to a centralized cloud-based system for in-depth analysis and decision-making. This aspect of our solution leverages the cutting-edge AI Core Operation platform, pioneered by Samsung SDS R&D Center Vietnam. Inspired by the principles of Machine Learning Operations (MLOps), our AI Core Operation platform is fortified by five key features:

- Data Storage: Aligned with MLOps philosophy, data storage is a critical component for future data reuse, facilitating AI model retraining and extracting valuable insights previously overlooked.

- System Management: To ensure the seamless operation of AI models deployed and the status of edge devices on the manufacturing floor, our system management feature is indispensable. It enables model version management and continuous monitoring of edge device performance, including CPU, memory, and program status.

- Advanced Analytics: Our platform goes beyond addressing inherent customer challenges by offering an advanced analytics tool. This empowers customers to uncover hidden facets of their data, facilitating comprehensive exploration and insights.

- Digital Transformation: Supporting digital transformation, our platform converts customer data into desired digital formats, optimizing data storage, transfer, backup, and retrieval processes.

- AI Online Training: At the heart of MLOps lies the crucial objective of maintaining a lifelong trained AI model. Our platform makes this a reality by enabling AI model retraining at any time, ensuring the model remains adaptive and continually enhancing its capabilities.

Case Studies

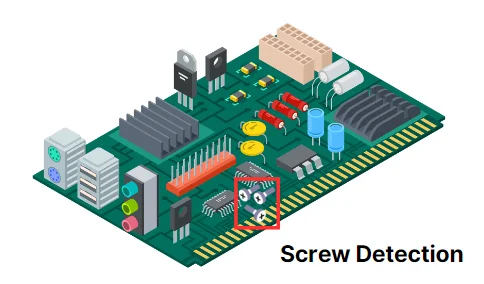

Screw Detection

In the context of laptop assembly manufacturing, the assurance of product quality is paramount. One critical aspect of this process involves the detection of foreign objects, such as loose screws, that may inadvertently find their way into the motherboard. Traditional quality control methods can struggle to identify these elusive issues. Our innovative AI-based vision inspection solution employs cutting-edge deep learning technology, meticulously trained on a vast dataset of images depicting both ideal assemblies and those with misplaced screws. With exceptional precision and speed, our system ensures that no rogue screws escape detection, offering a dependable pass/fail verdict, thus safeguarding the integrity of laptop assembly processes and the final product.

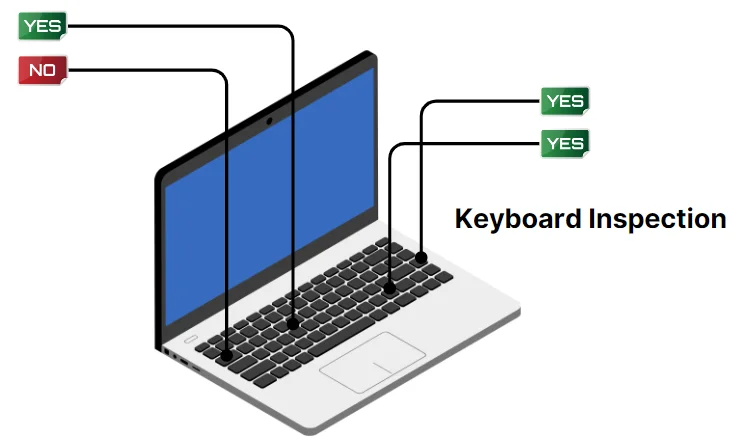

Keyboard Inspection

In the realm of laptop assembly manufacturing, uncompromising quality is non-negotiable. A critical challenge in this process lies in the meticulous inspection of keyboards to detect imperfections, misaligned keys, or other anomalies that can escape conventional quality control measures. Our advanced AI-based vision inspection solution brings a transformative approach to the table. Leveraging state-of-the-art deep learning technology, we’ve honed our system on an extensive dataset containing images of both pristine keyboards and those with potential defects. The result is a solution that excels in precision and swiftness, ensuring that no irregularity, no matter how subtle, eludes its scrutiny. By delivering swift and dependable pass/fail assessments, our solution plays a pivotal role in guaranteeing the excellence of laptop keyboards in the assembly process, contributing to the overall quality of the final product.

Workflow for Delivering the AI-based Vision Inspection

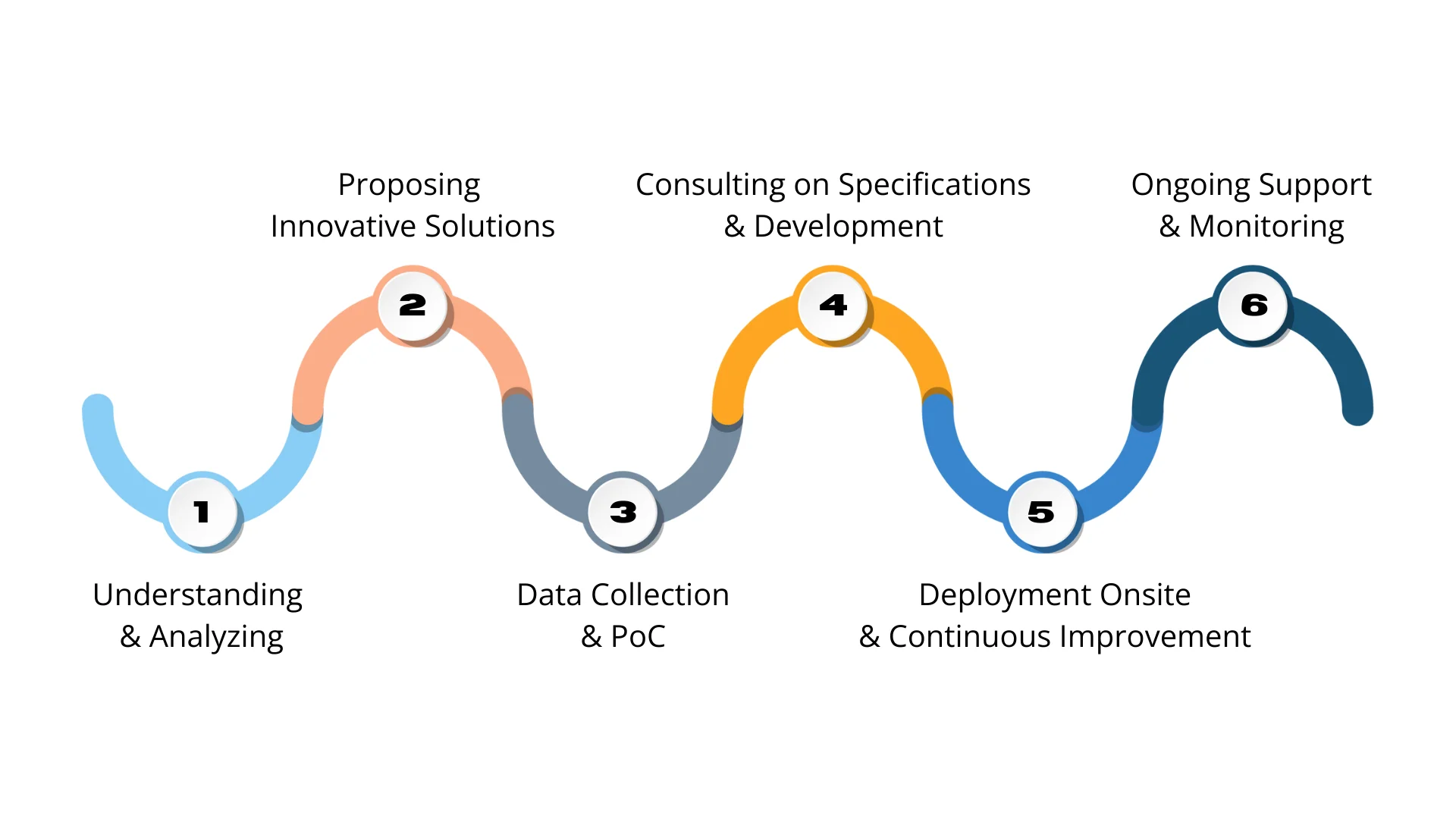

We present our workflow for introducing the AI-based Vision Inspection solution when engaging with a new customer including:

1. Understanding the Client’s Needs and Analyzing the Existing System:

– Begin by comprehensively understanding the specific requirements and challenges outlined by the client.

– Analyze any existing inspection systems or processes to identify their strengths and weaknesses.

2. Proposing Innovative Solutions:

– Based on the client’s needs, propose innovative solutions that address their specific inspection challenges.

– Emphasize how AI and computer vision can enhance existing systems or create entirely new solutions.

3. Data Collection and Proof-of-Concept (PoC) Development:

– Collect and preprocess the data required for developing a proof-of-concept (PoC).

– Develop a PoC version of the AI-based vision inspection system.

– Present the results of the PoC to the client, seek feedback, and make necessary adjustments to refine the PoC.

4. Consulting on Necessary Specifications and Solution Development:

Based on the PoC’s results and client feedback, offer recommendations for:

– Camera selection and configuration.

– Lens choices to optimize image capture.

– Lighting solutions to ensure consistent and high-quality imagery.

– Specifications for edge computing devices to meet processing requirements.

5. Solution Deployment Onsite and Continuous Improvement:

– Implement the developed solution at the client’s manufacturing site, seamlessly integrating it into their production process.

– Provide training and guidance to the client’s staff on system operation and maintenance.

– Establish a protocol for continuous improvement, including regular software updates, model retraining, and hardware maintenance.

– Continuously monitor and evaluate system performance in real-world conditions, making necessary adjustments.

6. Ongoing Support and Performance Monitoring:

– Offer continuous support to address issues, answer questions, and resolve system-related challenges.

– Continuously monitor system performance and provide regular reports to the client.

Getting Started with AI-based Vision Inspection

Our AI-Based Vision Inspection solution is a game-changer for manufacturers looking to enhance their production quality control processes. This cutting-edge technology brings unprecedented accuracy and efficiency to the inspection of products, helping to detect defects and anomalies with remarkable precision. To explore the full spectrum of capabilities and discover real-world use cases for our AI-Based Vision Inspection, we invite you to delve deeper by visiting our marketing video in action. Embrace the future of quality control with our AI-Based Vision Inspection solution.

Reference

[1] Boosting Vietnam’s manufacturing sector: From low cost to high productivity